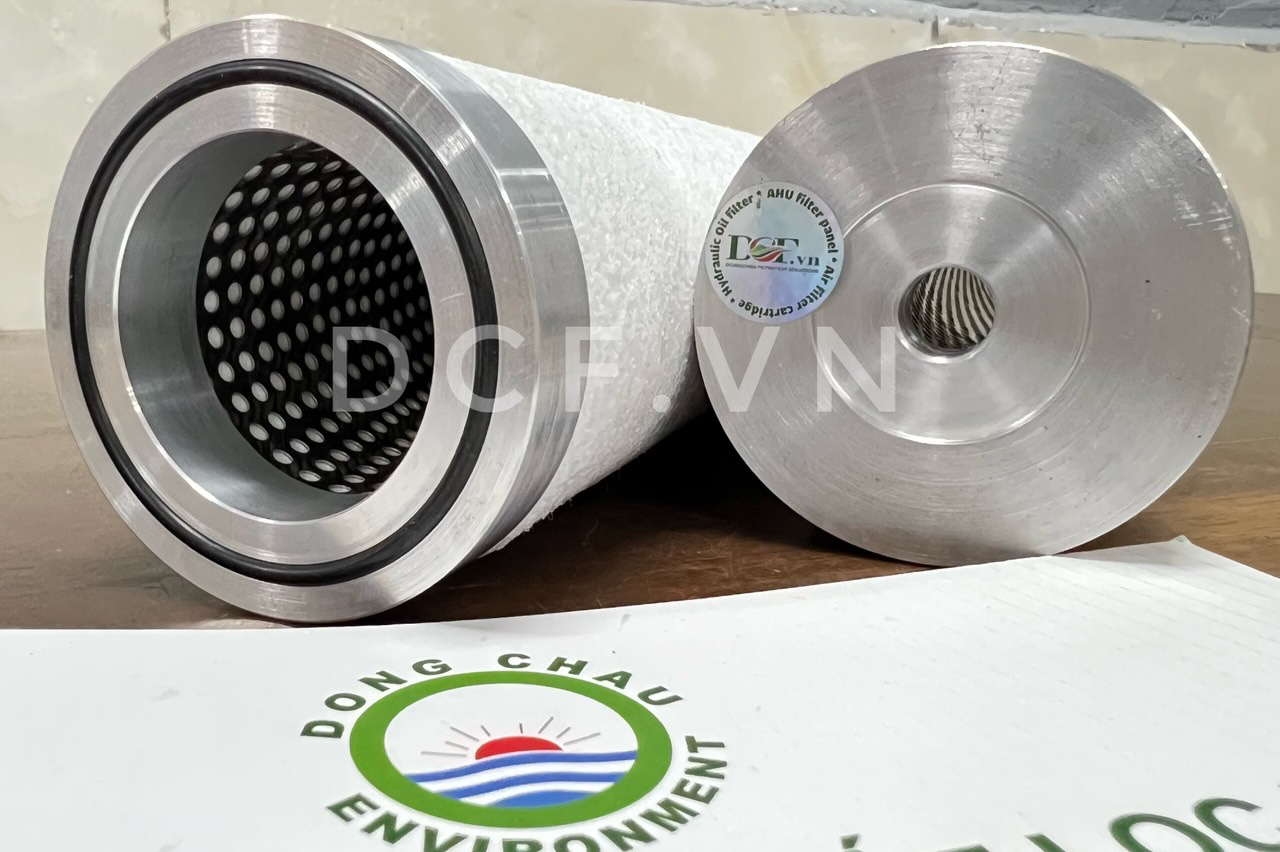

Oil vapor filters are devices that remove oil vapors from the air stream in industrial applications. Oil vapors can be generated by various processes, such as compressors, turbines, engines, pumps, and other machinery. Oil vapors can cause several problems, such as:

- Reducing the efficiency and performance of the equipment

- Contaminating the product or the environment

- Creating health and safety hazards for workers and customers

- Increasing the maintenance and operating costs of the system

Oil vapor filters use different technologies to capture and eliminate oil vapors from the air. Some of the most common types of oil vapor filters are:

Activated carbon filters: These filters use activated carbon, a porous material that adsorbs oil molecules on its surface. Activated carbon filters have a high capacity and can remove oil vapors at low concentrations. However, they also have some drawbacks, such as:

- They need to be replaced or regenerated periodically, as they become saturated with oil

- They can generate pressure drop and increase the energy consumption of the system

- They can be affected by humidity and temperature changes

Adsorption filters: These filters use adsorbents, such as silica gel, alumina, or molecular sieves, that attract oil molecules to their surface by physical or chemical forces. Adsorption filters have a lower capacity than activated carbon filters, but they can remove oil vapors at higher concentrations. They also have some advantages, such as:

- They can be regenerated by heating or purging with dry air or inert gas

- They have a low pressure drop and energy consumption

- They are resistant to humidity and temperature changes

Condensation filters: These filters use a cooling system to lower the temperature of the air stream below the dew point of the oil vapors. This causes the oil vapors to condense into liquid droplets, which are then separated by gravity or centrifugal force. Condensation filters can remove oil vapors at any concentration, but they also have some limitations, such as:

- They require a refrigeration unit and a condensate drain system

- They have a high energy consumption and operating cost

- They can create ice formation and corrosion issues

Oil vapor filters are essential components for many industrial applications that involve oil-lubricated machinery. By choosing the right type of oil vapor filter for your specific needs, you can improve the quality of your product, protect your equipment, and ensure a safe and healthy working environment.

Nhóm chuyên viên tư vấn sản phẩm Đông Châu

KD1: 0901325489 - kinhdoanh@sanphamloc.com.vn

KD2: 0906893786 - dongchau8@dongchau.net

KD3: 0909374589 - muahang@dongchau.net

KD4: 0906882695 - hotrokhachhang@sanphamloc.com.vn

KD5: 0902490389 - baogia@sanphamloc.com.vn

KD6: 0938958295 - locbui@sanphamloc.com.vn

KD7: 0902703986 - dongchau9@dongchau.net